How to Choose the Right Screen Printing Mesh Size

Information about screen printing mesh size: screen printing process may need different sizes mesh for different kinds of application. The size of screen printing mesh means the number of threads of the mesh is crossing per square inch. The higher number of the mesh is the indication of the fine threads and holes are on the screen. It is directly relevant to how detailed your image is and how thick the ink you are using.

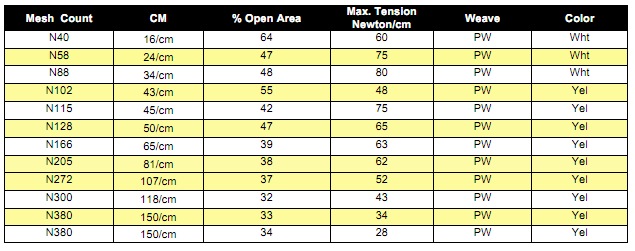

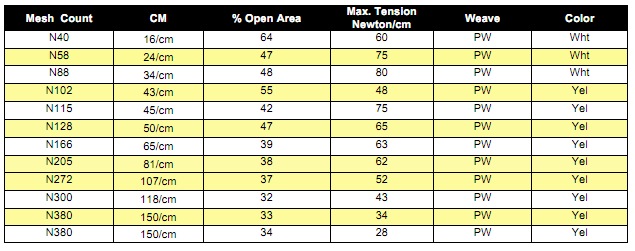

The dots in the image will fall into the holes in the mesh. It will not give you the correct representation of what about your image. Moreover, if you use a thinner ink, it will flood through the larger holes and soak onto your printing substance. Whenever you are trying to print a thicker into high of a mesh screen it will print through the mesh. When you found the difference in size from different companies, you will also see that mesh count is fairly close. The basic standard sizes of screen printing mesh are 110 and 156. They are great for text letters and larger spot color designs. Lower mesh count (40 to 86) is used for shimmer and glitter inks. If you printing substance have large particles you should use 40 to 60 or mesh screen. You will need to use 200 and 300 mesh your printing substance is used for detailed images and thinner inks. Highest mesh as 355, 380 and 400 are used mainly for graphics printing. UV inks which are extremely used in this printing.

Different kind of screen printing mesh sizes used for better screen printing and they hold the different amount of emulsion. For example, 60 mesh screens will hold much more emulsion than a 305 mesh screen. You should use it carefully and if the deferent is extreme, you should control your exposure times slightly for different screen printing mesh sizes.

screen printing mesh size